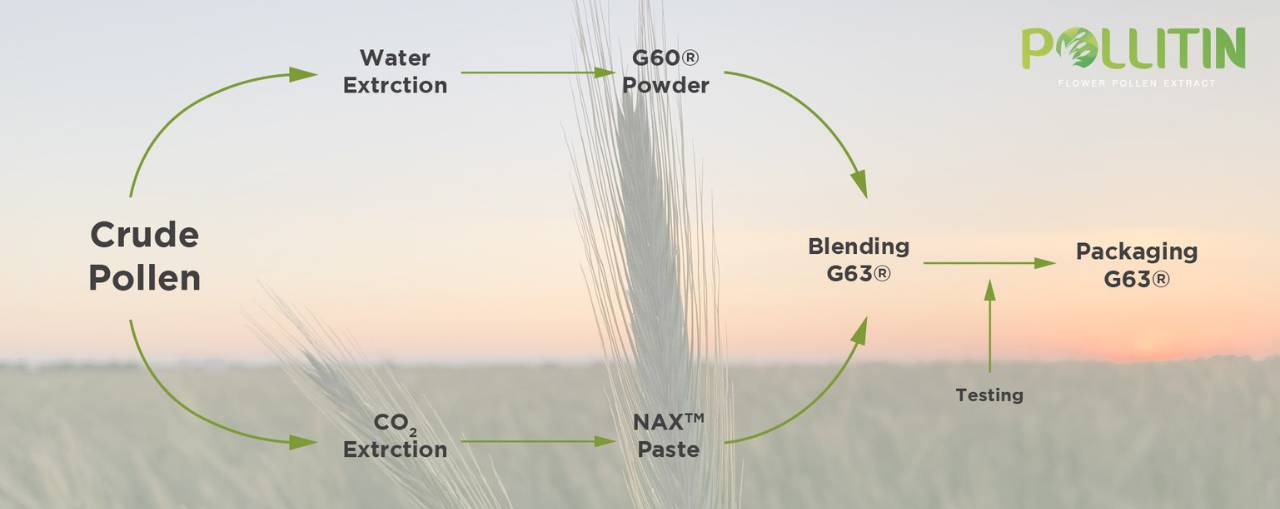

Proprietary Extraction Process – Supercritical CO2 & H2O Extraction

Our partner has researched and invented the production method. Pollen products start from the selection of Non-GMOs plant seeds without using pesticides and herbicides the last step is to harvest pollen with modern machinery and extract pollen by a proprietary process and filter by technique method sterilize to remove contaminants and eliminate allergens and quality control by analyzing the intensity of active ingredients, production processes, stability of products to determine the expiration of the product, control the quality of physical properties and chemical properties, as well as evaluation of filling systems and containers.

The broken pollen grains are centrifuged to separate the nutritious components from the allergens. Then, the nutrients in the pollen are extracted according to their nutritional benefits. The rest are recycled and used in various industries.

Collecting pollen.

Pollen collection started for a short time. In just two weeks, this is where non-solvent Pollitin™ Flower Pollen Extract ™ sources are available. Our field technicians are well-trained in the control of specially designed harvesters to get the most production in each area harvesters feature a unique dosing system that can maintain yield integrity and minimize pollen loss. Our field experts will closely monitor each harvested site to determine the optimal harvest date and notify the operator of this important information.

Raw material drying process

Raw materials that are still wet from the fields are transported by harvested trucks for further feeding, following a well-controlled drying phase. The wet raw material will be transported and continue to pay with a forklift operator trained on cGMP standards for material handling. Raw materials are dispensed to the drying drum using a well-controlled material distribution system to meet Pollitin™ quality control standards, programmable dedicated heaters regulate the temperature and supply air to each drying tank to have constant control for maximum efficiency. At each process, raw materials are checked and recorded to ensure the same quality of raw materials. Quality-certified raw materials are dispensed from a drying drum for processing to obtain the required pollen.

Storage and processing

Separation and pollination

Proper plant raw materials are sucked in through a special filtration device using the air supply system to separate pollen from each other. A closed system ensures that no pollen is lost. The measurements were taken in a collection bag which would then be kept in a cold storage area as the next step. From the farm step to the finished Pollitin™ formulas. All ingredients can be precisely controlled. The formulation of Pollitin™ Rye Flower Pollen Extract is the scientific knowledge required for the pharmaceutical industry.

Laboratory

Our partner laboratory helps to ensure quality and testing that specific conditions are met. The test equipment guarantees the same pollen quality. Each batch of pollen is tested to ensure it is free from toxins and pesticides. Testing for Pollitin™ Rye Flower Pollen Extract nutrients, such as amino acids, nucleic acid, enzymes & co-enzymes, cyclic-hydroxamic acid, minerals, phytosterols, isoflavones, and fatty acids, was performed using the HPLC and UV-Spectrometry methods.